What is full auto vertical ice tube packing machine?

Full auto vertical ice tube packing machine is a specialized equipment designed to automate the packaging process of ice tubes or ice sticks in a vertical form-fill-seal (VFFS) configuration. This machine is specifically tailored to handle the unique characteristics of ice tubes and ensure efficient and hygienic packaging.

The full auto vertical ice tube packing machine streamlines the packaging process for ice tubes, providing increased efficiency, productivity, and hygiene. It is commonly used in the food and beverage industry, catering services, and ice manufacturing facilities where ice tubes are packaged for retail or commercial distribution.

Live video

What are the applications of full auto vertical ice tube packing machine?

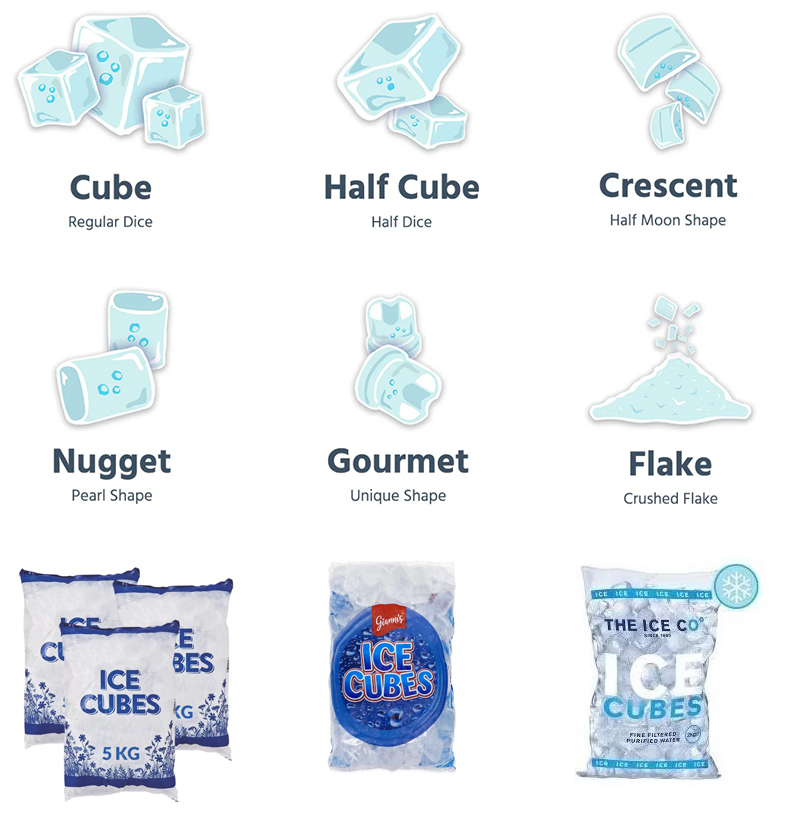

Full auto vertical ice tube packing machine can be used to pack many types of ice products, including but not limited to the following:

Ice cubes: Can be used to pack ice cubes of various sizes and shapes.

Ice puck: Ice puck that can be packaged and shaped, usually used in bars, restaurants and home use.

Popsicles: Various flavors of popsicles can be packaged, including fruit popsicles, cream popsicles, chocolate popsicles, etc.

Shaved ice: Shaved ice products can be packaged and used to make smoothies, ice cream and other cold desserts.

How does full auto vertical ice tube packing machine works?

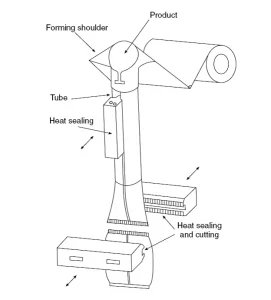

The full auto vertical ice tube packing machine operates by automatically feeding ice tubes into the packaging area. It then accurately measures and fills each ice tube with the desired amount of ice. Once filled, the machine seals the ice tubes to ensure product freshness and prevent any leakage or contamination during transportation and storage. The entire process is controlled by an advanced system, ensuring precise control and efficient packaging of ice tubes.

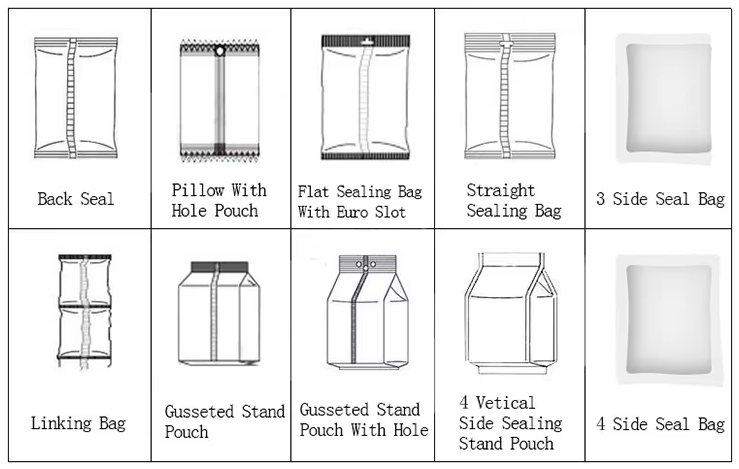

Optional packaging types

The ice cube packaging machine can achieve a variety of packaging types, including back seal, connected bags, pillow bags with holes, gusseted bracket bags, Euro slot flat seal bags, diagonal bracket bags with holes, straight seal bags, 4 vertical side seal bracket bags, 3-side seal bags and 4-side seal bags.

Packaging Materials

Ice cube packaging machine has a variety of packaging material options, including transparent film, aluminum foil film, color printed transparent film and color printed film. Transparent film can show the clear appearance of ice cubes, aluminum foil film provides good heat insulation and moisture resistance, color printed transparent film can increase the attractiveness and brand image of the product, and color printed film can bring more creativity and personalized options to ice cube packaging.

Ice cube packaging machine has a variety of packaging material options, including transparent film, aluminum foil film, color printed transparent film and color printed film. Transparent film can show the clear appearance of ice cubes, aluminum foil film provides good heat insulation and moisture resistance, color printed transparent film can increase the attractiveness and brand image of the product, and color printed film can bring more creativity and personalized options to ice cube packaging.

Fully Automatic Vertical Tube Ice Packaging Machine of advantages

Specially designed packaging: specially designed for packaging 1kg to 2kg of ice cubes, and minimize the gap during the packaging process to ensure a tight fit between the ice cubes and the bag.

Fully automatic and efficient packaging: the packaging speed can reach 30-40 bags per minute, improving production efficiency.

Advanced heat sealing technology: the machine adopts advanced heat sealing technology to ensure the sealing and safety of ice cube packaging bags.

Unique clip design: the ice tube packaging machine bucket is equipped with a clip before the ice cubes slide into the bag, which is used to clamp the ice cubes for a period of time before putting them into the bag for packaging.

Humanized design: the bag is made of PE material. Compared with the composite film used by other manufacturers, the PE bag can prevent the bag from easily rotting during storage, and improve the durability and quality of the packaging.

Full auto vertical ice tube packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of full auto vertical ice tube packing machine

The full auto vertical ice tube packing machine consists of several key components, including an ice feeding system, tube formation mechanism, ice filling mechanism, sealing method, cutting mechanism, and control system. These components work together to automate the process of packaging ice into tube-shaped bags, ensuring efficient and hygienic packaging.

Customer case

| Packaging Case | Packaging Materials | Packing volume | Packing size | Customer feedback |

| A beverage manufacturing company - Ice Tube Packaging | Ice Tubes (cylindrical ice cubes used to cool beverages) | 2000-2500 ice tubes are packed per hour. | 20 ice tubes are packed in each bag, and the bag size is 30cm (length) × 15cm (width). | The beverage manufacturing company needed to quickly and efficiently package the ice tubes into small bags for easy distribution to the catering industry. The fully automatic vertical ice tube packaging machine significantly improves production efficiency and reduces labor costs through precise counting and high-speed packaging |

| A cold chain logistics company - ice tube transportation packaging | Ice tubes (ice cubes used to keep low temperature during cold chain transportation) | 1500-1800 ice tubes are packaged per hour. | 10 ice tubes are packaged per bag, and the bag size is 25cm (length) × 12cm (width) | The cold chain logistics company needs to pack the ice tubes into small bags for cold chain transportation boxes of different specifications. The fully automatic vertical ice tube packaging machine meets the needs of different customers through the flexible bag size adjustment function, while ensuring the sealing and durability of the packaging |

| A food processing plant - ice tube food preservation packaging | Ice tubes (ice cubes used for preservation during food processing) | 3,000 ice tubes are packaged per hour | 50 ice tubes are packaged per bag, and the bag size is 40cm (length) × 20cm (width) | The food processing plant needs to package the ice tubes into large bags for the preservation link of the food processing line. The fully automatic vertical ice tube packaging machine meets the factory's high production needs through large-capacity packaging design, while reducing the waste of packaging materials |

Full auto vertical ice tube packing machine price

The price of a full auto vertical ice tube packing machine can vary depending on various factors such as the machine's capacity, features, brand, and the supplier or manufacturer you choose. Generally, full auto vertical ice tube packing machines can range in price from several thousand dollars to tens of thousands of dollars.

It's important to note that pricing information can change over time, and it's best to reach out directly to packaging machine suppliers or manufacturers for the most accurate and up-to-date pricing information. They can provide you with detailed quotes based on your specific requirements and provide information on any additional costs, such as installation, training, or warranty.

Why choose us as your top full auto vertical ice tube packing machine supplier?

Xinxiang Dahan is a professional manufacturer of full auto vertical ice tube packing machine. They are committed to providing high-quality, high-efficiency packaging equipment to meet the packaging needs of popsicle products. Xinxiang Dahan's fully automatic vertical popsicle packaging machine adopts advanced technology and innovative design to achieve high-speed and precise packaging process, and is widely used in food and beverage, hotel and retail industries. They have won the trust and praise of customers with their high-quality products, reliable after-sales service and rich industry experience. Whether it is small-scale production or large-scale production, Xinxiang Dahan can provide customized solutions to meet the specific needs of customers.