What is vertical powder packaging machine?

Vertical powder packaging machine is a type of packaging equipment specifically designed to package powdered products in vertical form-fill-seal (VFFS) packaging. It is commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics.

Vertical powder packaging machine can handle various powder products, including spices, flour, milk powder, protein powder, medicinal powder, etc. They can be adapted to different product characteristics and packaging requirements.

Various types of vertical powder packaging machine for sale

We provide fully automatic packaging equipment, semi-automatic packaging machines and manual packaging machines to meet the needs of different industries. These equipment are widely used in various fields such as food industry, beverage industry, chemical industry, cosmetics industry, pharmaceutical industry, etc.

Fully automatic packaging machine: It can package 1-50kg of powder, suitable for high-volume production environment, and has the characteristics of high automation. Through advanced control systems and precise weighing technology, these devices can quickly and accurately complete the packaging of powder.

Semi-automatic packaging machine: It combines manual operation and automation functions and is suitable for production scenarios with medium-volume requirements. It can package 500-1000g of powder, is simple to operate, and can improve production efficiency while maintaining a certain degree of flexibility.

Manual packaging machine: It is suitable for small-scale production and special packaging needs, and the price is relatively more economical. It can package 0-200 grams of powder.

How does a vertical powder packaging machine work?

The working principle of the vertical powder packaging machine can be introduced in the following brief steps:

The vertical powder packaging machine passes the powder from the storage hopper into the measuring hopper and is weighed by a precise weighing system; then, the powder is conveyed into the packaging bag, which is cut according to the preset length; then, the bag is sealed and printed with information such as the production date; finally, the packaging bag is output, completing the entire packaging process. The entire workflow is highly automated, and precise packaging operations are achieved through the control system, improving production efficiency and ensuring packaging quality.

What powder can the machine package?

Vertical powder packaging machine can be used to package various types of powders, including but not limited to the following:

1. Food powder: such as coffee powder, tea powder, cocoa powder, milk powder, condiments, flour, sugar powder, etc.

2. Cosmetic powders: such as facial mask powder, loose powder, eye shadow powder, blush powder, foundation, etc.

3. Pharmaceutical powders: such as herbal powders, pharmaceutical powders, vitamin powders, etc.

4. Chemical raw material powder: such as dye powder, pigment powder, plastic particles, rubber powder, etc.

5. Agricultural powder: such as pesticide powder, fertilizer powder, etc.

Live Video

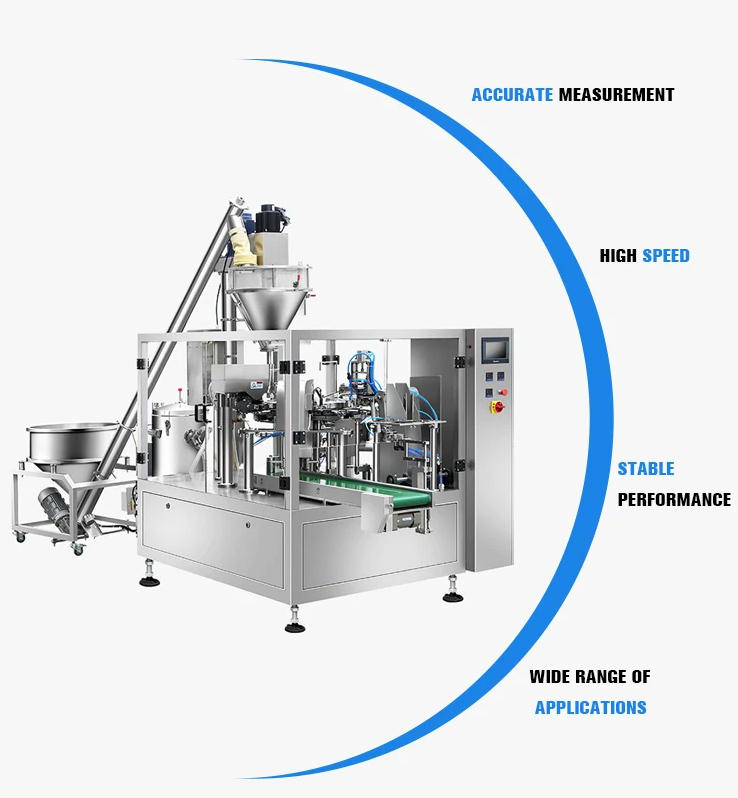

Features of vertical powder packaging machine

As a highly automated and efficient packaging equipment, vertical powder packaging machine has been widely used in food, medicine, chemical and other industries. Its unique structural design and working principle give it many advantages, mainly the following points.

1. Efficient production: It can quickly complete the measurement, packaging and sealing process of powder, suitable for mass production needs.

2. Precise measurement: The filling amount of powder can be accurately measured and controlled to ensure a consistent amount of powder in each packaging bag, improving product consistency and quality.

3. Flexible packaging forms: Vertical packaging machines can be used to produce a variety of packaging forms, such as vertical bags, vertical bags with zippers, vertical bags with nozzles, etc. The appropriate packaging form can be selected according to product characteristics and market demand.

4. Space-saving: Vertical packaging machines usually have a smaller footprint, adapt to production environments with limited space, and save production space to the greatest extent.

5. Good packaging effect: It can ensure the sealing and appearance of the packaging bag, effectively prevent problems such as powder leakage, oxidation and moisture, and extend the shelf life of the product.

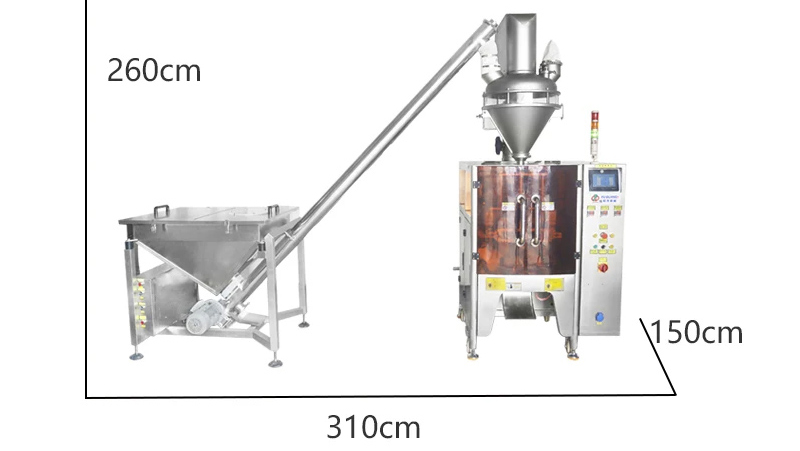

Vertical powder packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

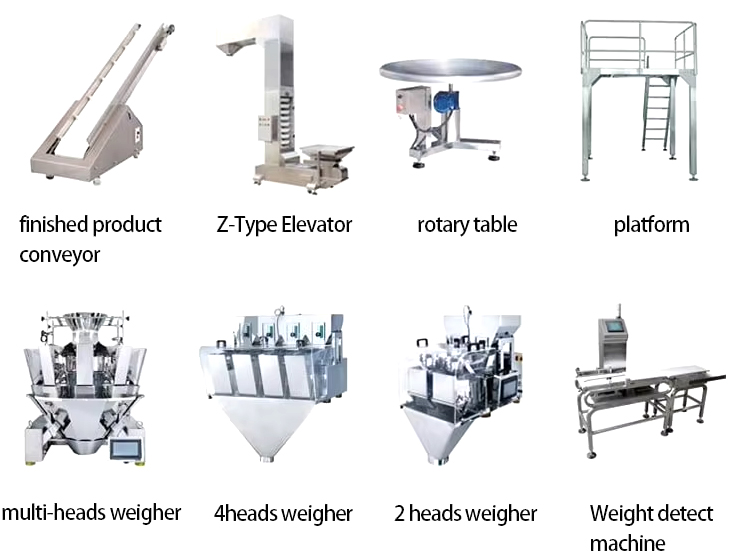

Available options

1.Bag Shape Options

Pillow bag/Gusset bag/Flat bottom stand up bag/Quad seal stand up bag/Brick shape bag/Bag with hanging hole/Bag with easy tear notch

2.Functional Options

Date printer/Quad seal bag assembly/Bag-in-bag configuration/Flat bottom bag assembly/Hole punch (Euro slot or round)/Load shelf/Product settler/Gas flush/Static elimination/Tear notch/In-feed and take-away conveyors/Integration with variety of printers, metal detectors, label applicators, and checkweighers

Customer case

Things you need to consider when buying a vertical powder packaging machine

When buying a vertical powder packaging machine, there are several important factors to consider:

1.Production Requirements: Determine your production volume and speed requirements to choose a machine that can meet your output targets efficiently.

2.Powder Characteristics: Consider the flowability, density, and consistency of the powder you will be packaging. Different powders may require specific feeding systems or auger designs to ensure accurate filling.

3.Packaging Materials: Evaluate the type and properties of the packaging materials you plan to use, such as film or pouches. Ensure that the machine is compatible with your chosen packaging materials and can handle the required thickness and size.

4.Sealing and Packaging Quality: Check the sealing mechanism and packaging quality assurance features to ensure proper sealing, preventing leakage, contamination, or spoilage of the powder.

5.Cost and Return on Investment: Consider the initial purchase cost, operating expenses (such as power consumption and maintenance), and the potential return on investment based on increased productivity, reduced labor costs, and improved product quality.

Why choose us as your top vertical powder packaging machine supplier?

Xinxiang Dahan is a well-known packaging machinery manufacturer with rich experience and good reputation. Its products are of reliable quality and its packaging machines have efficient and accurate metering and packaging capabilities, which can meet different output needs and ensure the consistency and consistency of the powder. Quality, this model is flexible and suitable for a variety of packaging specifications and forms to meet changes in market demand. Xinxiang Dahan also pays attention to product safety and compliance with relevant laws and regulations to ensure the safety of operators and product compliance. Finally, Xinxiang Dahan provides comprehensive after-sales support and maintenance services to ensure that customers can obtain timely technical support and spare parts supply, providing reliable guarantee for customers' production operations. Taking the above factors into consideration, choosing Xinxiang Dahan vertical powder packaging machine is a reliable choice, which can improve production efficiency, ensure product quality, and obtain good after-sales service.

Want to know the vertical powder packaging machine price?

1. Model

Small machine: suitable for small-scale production, low price.

Medium machine: suitable for medium-scale production, moderate price.

Large machine: suitable for large-scale production, high price.

2. Function

Basic type: only has basic packaging functions, low price.

Multifunctional type: has multiple functions such as metering, filling, sealing, coding, etc., high price.

Intelligent type: has advanced functions such as automatic detection, fault diagnosis, remote control, etc., and the highest price.

3. Capacity

Low-speed type: low capacity, low price.

Medium-speed type: moderate capacity, moderate price.

High-speed type: high capacity, high price.

4. Material

Ordinary material: suitable for general environment, low price.

Stainless steel material: suitable for high-standard environments such as food and medicine, high price.

After-sales service

Standard service: provides basic warranty and technical support, low price.

Value-added service: provides extended warranty, regular maintenance, on-site training, etc., high price.

5. Approximate price range

Small basic model: $2,740 - $6,850

Medium multifunctional model: $6,850 - $20,550

Large intelligent model: $20,550 - $68,500

6. Purchase advice

Clear demand: Choose the appropriate model according to production scale, material characteristics, packaging requirements, etc.

Compare brands: Choose a brand with high cost performance within the budget.

Inspect functions: Choose necessary functions according to actual needs to avoid unnecessary expenses.

Pay attention to after-sales service: Choose a supplier that provides good after-sales service to ensure long-term and stable operation of the equipment.