What is a spice vertical packaging machine?

Spice Vertical Packaging Machine is specially designed for accurate metering, packaging and sealing of spice powders, granules and other materials.Vertical Packaging Machine It is widely used in the packaging of chili powder, curry powder, spice powder and other powders.

What are the advantages of using a vertical packaging machine to package spices?

Vertical structure: The vertical packaging machine adopts a vertical structure design. Compared with the horizontal packaging machine, it occupies less ground space, is suitable for production environments with limited space, saves space and improves packaging efficiency.

Sealing system: The sealing system of the vertical packaging machine is usually well designed to ensure the sealing of the packaging bag and maintain the freshness and quality of the spices.

Good product visibility: The vertical structure of the vertical packaging machine allows the process of bagging or containerizing spices to be observed directly in front of the personnel, which is convenient for checking the packaging quality and appearance of the product, and timely discovering problems and making adjustments.

Flexible adaptation to diversified packaging needs: The vertical structure design of the vertical packaging machine enables it to adapt to packaging bags or containers of different shapes and specifications, such as vertical bags, bottles, cans, etc. It has strong flexibility and adaptability and can meet the packaging needs of different spice products.

Composition of spice vertical packaging machine

Feeding system: The feeding system is used to feed condiments into the packaging machine for packaging, and may include storage hoppers, metering devices, and conveying devices, etc.

Bag or container conveying system: This system is used to convey bags or containers so that they can move smoothly during the packaging process, and may include devices such as conveyor belts, rollers, or manipulators.

Filling system: The filling system is responsible for filling pre-measured condiments into bags or containers, and can achieve precise condiment filling operations.

Sealing system: The sealing system is used to seal bags or containers to ensure the sealing and freshness of condiments.

Control system: The control system is the core part of the entire packaging machine. Including electrical control cabinets, PLC controllers, and human-machine interfaces, etc.

Discharging system: The discharging system is used to discharge packaged spice products from the packaging machine.

How does the spice vertical packaging machine work?

The working process of the spice vertical packaging machine includes the steps of spice feeding, metering filling, bag or container conveying, sealing and discharging. The spices are fed through the feeding system, accurately filled into the bag or container by the metering device, then moved to the sealing position for sealing by the conveying system, and finally discharged from the packaging machine through the discharging system. The control system monitors and controls each component to ensure the stable operation of the packaging machine and efficient packaging effect.

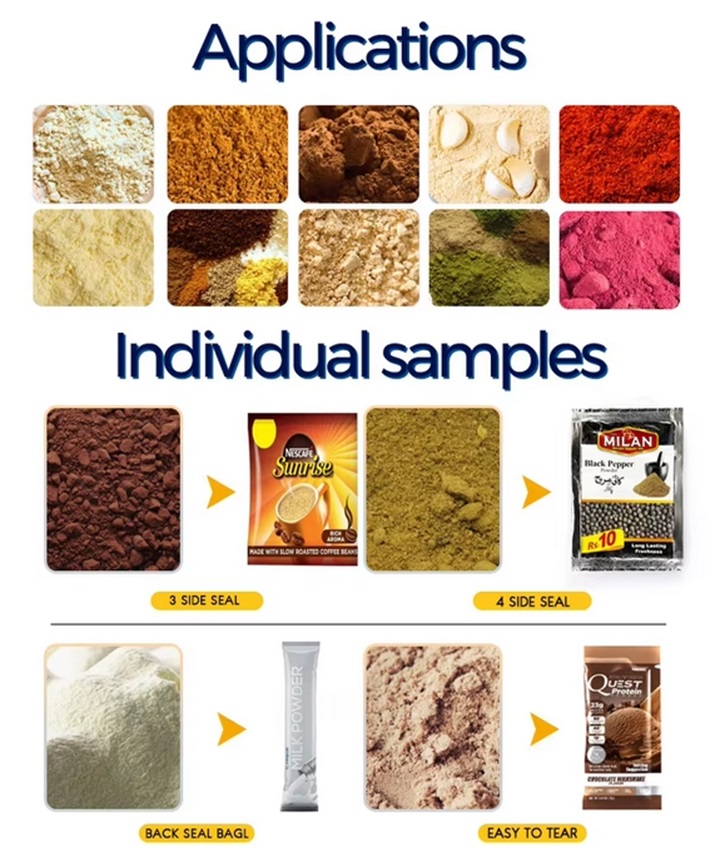

Application of spice vertical packaging machine

Powdered spice packaging: Spice vertical packaging machine can be used for the packaging of powdered spices (such as chili powder, curry powder, five-spice powder, etc.). Through precise metering devices and filling systems, powdered spices can be accurately filled into packaging bags or containers and sealed to maintain their fragrance and quality.

Granular spice packaging: Spice vertical packaging machine is suitable for the packaging of granular spices (such as peppercorns, star anise, peppercorns, etc.). It can measure and fill different particle sizes as needed to ensure that the number of granular spices in each bag or container is accurate and consistent.

Flake spice packaging: For flaky spices (such as dried ginger slices, bay leaves, etc.), the spice vertical packaging machine can accurately fill them into packaging bags or containers and seal them to maintain their shape and freshness.

Mixed spice packaging: Spice vertical packaging machine can also be used for the packaging of mixed spices. It can accurately mix multiple spices according to preset formulas and package them to meet the needs of specific seasonings or formulas.

How do I choose a packaging machine?

When choosing a vertical spice packaging machine, you should first consider the scale of production and demand, and determine the packaging speed and accuracy requirements. Secondly, you need to consider the applicable packaging specifications and materials to ensure that the machine can adapt to the required packaging. Ease of operation and maintenance are also important considerations to improve production efficiency. Brand reputation and after-sales service guarantee the quality and stability of the equipment. Price and cost-effectiveness need to be balanced to choose a model that fits your budget. Finally, technical support and training can help make full use of the equipment's functions. In summary, it is key to choose a vertical spice packaging machine that suits your needs, taking into account production needs, packaging specifications, ease of operation, brand reputation, price and after-sales service.

Saturday July-20 2024 17:46:21