What is a vertical particle packaging machine?

Vertical particle packaging machine is a specialized equipment designed for packaging particles or granular materials in a vertical form-fill-seal process. It is commonly used in industries such as food, agriculture, pharmaceuticals, and chemical manufacturing.

Vertical particle packaging machines offer efficient, accurate, and hygienic packaging solutions for granular or particulate products. They help improve productivity, maintain product quality, and ensure proper packaging for various industries that require precise and reliable packaging.

Different types of vertical particle packaging machine for sale

-

Large vertical granule packaging machine

The large vertical granule packaging machine has higher production capacity and is suitable for enterprises that need to produce products continuously, such as large food factories, pharmaceutical factories and daily necessities factories.

-

Automatic vertical granule packaging machine

The automatic vertical granule packaging machine can automatically complete all packaging processes and is suitable for enterprises that need to produce granule products in large quantities, such as food factories, pharmaceutical factories and daily necessities factories.

-

Semi-automatic vertical granule packaging machine

The semi-automatic vertical granule packaging machine requires manual completion of some processes, such as putting products into the hopper or putting packaging bags on the conveyor belt. It is suitable for enterprises that need to pack medium-volume products, such as small food factories, handicraft workshops, etc.

-

Small vertical granule packaging machine

The small vertical granule packaging machine is small in size and cheap in price. It is suitable for small enterprises that pack small quantities of products. It is used to pack granule products such as candy, nuts, and grains.

-

Multi-head vertical granule packaging machine

The multi-head vertical granule packaging machine has multiple independent filling heads and can fill multiple packaging bags at the same time. It is suitable for enterprises that need to produce multiple products in large quantities, such as food factories, pharmaceutical factories and daily necessities factories.

-

Multifunctional vertical granule packaging machine

The multifunctional vertical granule packaging machine can complete a variety of packaging functions and is suitable for enterprises that need multifunctional packaging machines, such as food factories, pharmaceutical factories, daily necessities factories and hardware factories.

How does vertical particle packaging machine work?

Vertical particle packaging machines work by feeding product from a hopper into a packaging material, which is then sealed around the product to form a package. The packaging material is typically a roll of film, which is unwound and formed into a tube around the product. The tube is then sealed at the top and bottom, and the package is cut off from the roll.

Live Video

What are the advantages of vertical granule packaging machine?

1. Efficient and Fast

Vertical granule packaging machines are designed for high-speed packaging, processing 30-300 bags per minute, depending on the model and material; they significantly increase production efficiency compared to manual or semi-automatic packaging methods.

2. Precise and Accurate

These machines use advanced weighing and filling systems (e.g., load cells or volumetric fillers) to ensure precise measurement of granules; this reduces material waste and ensures consistent product quality.

3. Automated and Labor-Saving

These machines automate the entire packaging process, including bag making, filling, sealing, and cutting; this reduces the need for labor, reduces labor costs, and minimizes human error.

4. Compact Design

Vertical granule packaging machines have a small footprint, making them ideal for facilities with limited space; their vertical orientation allows for efficient use of floor space.

What are the applications of vertical particle packaging machine?

Vertical granule packaging machines are particularly suitable for the packaging of granular products. They are widely used in many industries and can meet the packaging needs of different granular products. They are one of the important equipment for many companies in the field of granular product packaging. The following are some common application areas of vertical granule packaging machines:

Food industry: such as coffee beans, candies, nuts, puffed foods, biscuits, dried fruits, condiments, etc.

Pharmaceutical industry: such as tablets, capsules, granular drugs, etc.

Cosmetics industry: such as foundation, eye shadow, blush, loose powder, etc.

Agricultural industry: such as seeds, fertilizers, feed, etc.

Chemical industry: such as plastic particles, pigments, additives, etc.

Daily necessities industry: such as washing powder, dishwashing powder, detergent, shampoo, etc.

Hardware industry: such as screws, nuts, bolts, etc.

Customer case

| Packaging Case | application | Results |

| A food processing plant | Used for packaging puffed food, nuts, candy and other granular foods. | By using a vertical granule packaging machine, efficient and continuous packaging is achieved, with a packaging speed of 30-50 bags/minute, and the packaging bags are beautifully sealed and meet food safety standards |

| A chemical company | Used for packaging granular chemical raw materials, such as catalysts, fillers, etc. | The equipment can automatically complete the processes of metering, filling, bag making, date printing, etc., which significantly improves production efficiency and reduces labor costs. |

| A pharmaceutical company | Used for packaging pharmaceutical products such as tablets and capsules. | The equipment supports high-speed packaging, up to 300 times/minute, and complies with GMP regulations to ensure the hygiene and safety of drug packaging. |

| An agricultural processing plant | Used for packaging granular agricultural products such as rice and corn. | The equipment realizes fully automatic packaging, with a packaging range of less than 1200ml, suitable for packaging needs of various specifications |

| An electronic materials factory | Used for packaging electronic materials such as silicon powder. | The equipment adopts a fully sealed design to effectively prevent dust leakage, improve the working environment, and improve packaging efficiency |

Vertical particle packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

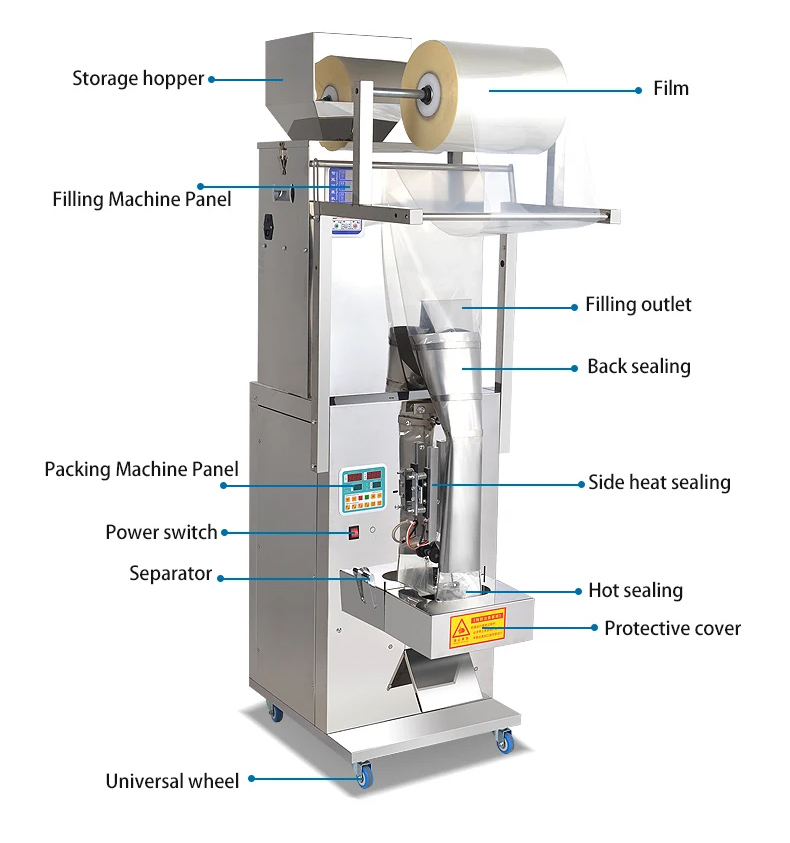

Structure of vertical particle packaging machine

The structural design of the vertical granule packaging machine is usually simple and clear, and each component works closely together to realize the automated packaging process of granule products. The following are the main structural components of the vertical granule packaging machine:

Frame: The frame of the vertical particle packaging machine is constructed from sturdy materials such as stainless steel or aluminum. It provides structural support and stability to the entire machine.

Product Hopper: The product hopper is located at the top of the machine. It stores the bulk product that needs to be packaged. The hopper is usually equipped with an agitator to ensure a consistent flow of product.

Forming Tube: The forming tube is a cylindrical or rectangular tube that shapes the packaging material into a vertical pouch. It is typically made of thin, flexible material such as polyethylene or polypropylene.

Filling System: The filling system is responsible for delivering the product from the hopper into the formed pouch. It can be a volumetric filler, auger filler, or a net weigh filler, depending on the product and packaging requirements.

Sealing System: The sealing system consists of two heated sealing jaws that press together to seal the pouch at the top and bottom. The sealing jaws are coated with a non-stick material to prevent the product from sticking.

Conveyor System: The conveyor system transports the filled and sealed pouches away from the packaging area. It can be a belt conveyor, roller conveyor, or a combination of both.

Control Panel: The control panel is usually located at the front of the machine. It allows the operator to adjust various parameters such as packaging speed, filling weight, and sealing temperature.

Packing material

Polyester/aluminizing/Polyethylene, polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

What is the vertical granule packaging machine price?

The price of a vertical granule packaging machine can vary depending on various factors such as the machine's specifications, features, brand, and the supplier or manufacturer. Additionally, market conditions and geographical location can also influence the price.

To get an accurate price for a vertical granule packaging machine, it is recommended to reach out to suppliers or manufacturers directly. They can provide you with detailed information about the machine's pricing based on your specific requirements and any additional customization or features you may need.

Tips to choose a correct vertical granule packaging machine?

When choosing a vertical granule packaging machine, consider the following tips to ensure you select the most suitable machine for your needs:

Packaging Requirements: Assess your specific packaging requirements, such as the type and characteristics of the granules, desired packaging speed, bag sizes and styles, and production capacity. This will help you determine the necessary features and specifications of the machine.

Machine Features: Look for features that align with your requirements. Consider factors such as the type of filling mechanism (auger, multi-head weigher, piston), bag forming and sealing methods, control system, ease of operation and maintenance, and compatibility with different packaging materials.

Customization Options: Check if the machine can be customized to meet your specific needs, such as adding additional features or integrating with existing production lines. Customization can enhance efficiency and productivity.

Price and Budget: Determine your budget and compare prices from different suppliers. Consider the overall value offered by the machine, including its quality, features, and long-term performance, rather than solely focusing on the initial cost.

Vertical granule packaging machine manufacturers

Xinxiang Dahan is a manufacturer specializing in the manufacture of vertical granule packaging machines. They have extensive experience and expertise in the field of packaging machinery and are committed to providing customers with high-quality, reliable solutions. Xinxiang Dahan's Vertical granule packaging machine is famous for its advanced technology, stable performance and efficient packaging capacity, and is suitable for the packaging needs of various granular materials. They also provide comprehensive pre-sales consultation, in-sales support and after-sales service to ensure customer satisfaction and smooth ongoing operations.