What is premade pouch rotary fill & seal packing machine?

Premade pouch rotary fill & seal packing machine is a type of packaging equipment that is specifically designed to handle pre-formed pouches or bags. It automates the process of filling these pouches with product and sealing them for packaging purposes.

The premade pouch rotary fill & seal packing machine offers versatility and flexibility in packaging various products. It provides efficient, hygienic, and automated packaging solutions, helping manufacturers improve productivity, reduce labor costs, and maintain the quality and integrity of their products.

Types of premade pouch rotary fill & seal packing machine

There are various types of premade pouch rotary fill and seal packing machines available, each designed to accommodate different pouch styles, sizes, and packaging requirements. Here are some common types:

Rotary Pre-made Pouch Fill and Seal Machine: This is a standard type of premade pouch packing machine that can handle a wide range of pouch styles, including flat pouches, stand-up pouches, and doypacks. It offers high-speed filling and sealing capabilities with precise control over the filling process.

Rotary Pre-made Pouch Fill and Seal Machine with Zipper Applicator: This type of machine is equipped with an additional module that applies zippers to the premade pouches. It allows for easy resealing of the pouch after opening, providing convenience and maintaining product freshness.

Rotary Pre-made Pouch Fill and Seal Machine for Spouted Pouches: This machine is specifically designed to handle premade pouches with spouts. It can accurately fill and seal spouted pouches, commonly used for liquid or semi-liquid products such as sauces, beverages, and baby food.

Rotary Pre-made Pouch Fill and Seal Machine for Stick Packs: Stick pack machines are specially designed for packaging elongated, narrow pouches commonly known as stick packs. These machines can efficiently fill and seal stick packs, often used for single-serve or sample-sized products like sugar, coffee, and instant beverages.

Rotary Pre-made Pouch Fill and Seal Machine for Retort Pouches: Retort pouches are designed for products that require high-temperature processing or sterilization. Machines specialized in handling retort pouches are equipped with features to withstand the heat and pressure involved in the retort process.

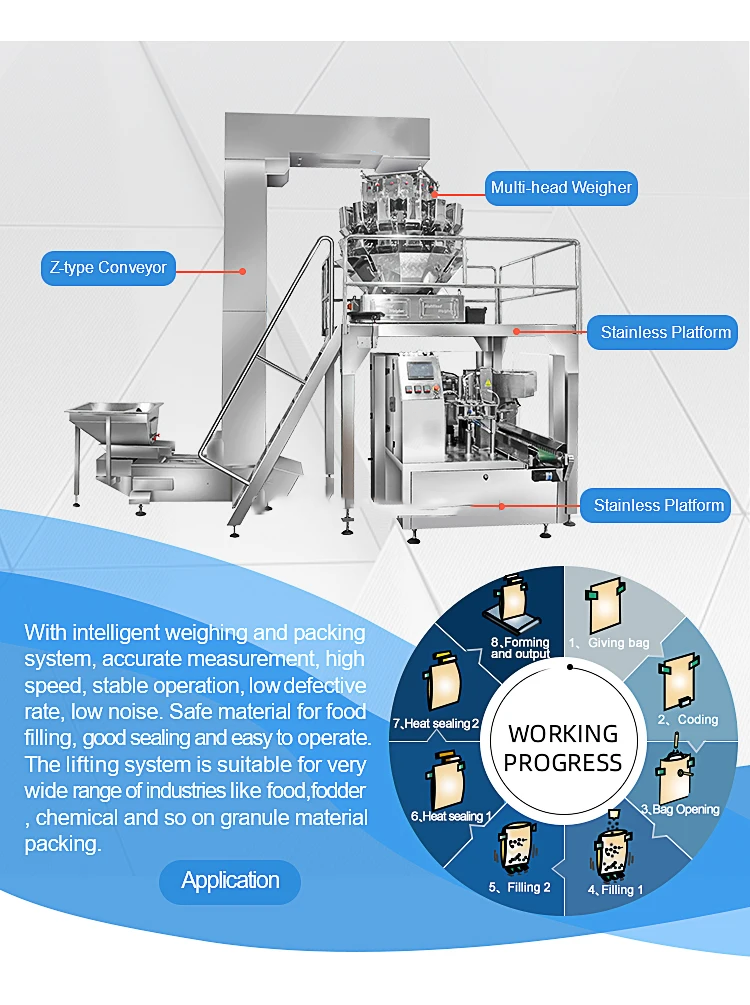

How does premade pouch rotary fill & seal packing machine works?

Premade pouch rotary fill & seal packing machines work by automatically filling and sealing premade pouches. The machine rotates a carousel that holds the pouches, and as they move along the rotary system, they go through different stations.

First, the pouches are opened and positioned for filling. Then, the desired product, such as powders or granules, is accurately measured and dispensed into the pouches. After filling, the pouches move to the sealing station where the top of the pouch is sealed.

Next, the pouches continue their rotation to the final sealing station, where the remaining sides of the pouch are sealed, ensuring a secure and airtight packaging. The filled and sealed pouches are then discharged from the machine for further processing or distribution.

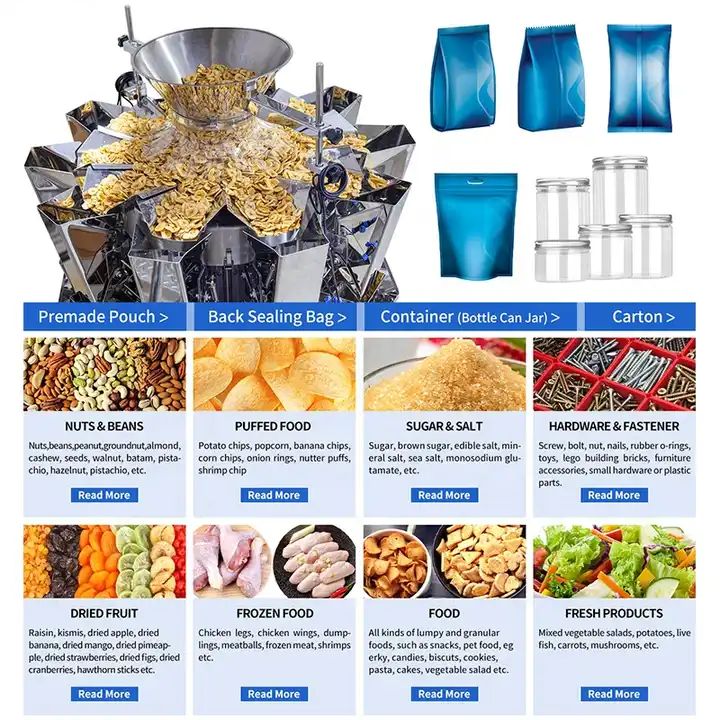

What are the applications of premade pouch rotary fill & seal packing machine?

The pre-made bag rotary filling and sealing packaging machine can efficiently complete the filling, sealing and packaging process of powder products, improve production efficiency, ensure packaging quality, and is widely used in production lines in many different industries. The following are the application scenarios of the pre-made bag rotary filling and sealing packaging machine

Food Products: The machine is widely used in the food industry for packaging products such as snacks, chips, cookies, candies, nuts, coffee, tea, spices, pet food, and more. It ensures efficient and hygienic packaging of food products in preformed pouches.

Beverages: The machine can be used for packaging liquid or powdered beverages, including juice, milk, water, energy drinks, instant coffee, powdered drink mixes, and more. It provides a reliable and automated solution for filling and sealing beverage pouches.

Pharmaceuticals and Medical Products: The machine is suitable for packaging pharmaceuticals, medical devices, and healthcare products in preformed pouches. It ensures accurate filling and sealing, maintaining the integrity of the products and meeting the required hygiene standards.

Chemical Products: The machine can be used for packaging industrial and chemical products, such as fertilizers, pesticides, detergents, powders, and granules. It provides a reliable and efficient solution for filling and sealing preformed pouches containing these products.

Pet Food and Treats: The machine is commonly used in the pet food industry for packaging dry pet food, treats, and snacks. It ensures accurate filling and sealing of preformed pouches, maintaining the freshness and quality of the pet food products.

What are the characteristics of pre-made bag rotary fill seal packaging machine?

The characteristics of pre-made bag rotary fill and seal packaging machine make it a commonly used packaging equipment in various industries. It can meet diverse packaging needs and provide efficient, accurate and reliable packaging solutions.

Efficiency: These machines are designed for high-speed packaging, allowing for efficient and rapid filling and sealing of premade pouches. This can significantly increase production output and reduce labor costs.

Versatility: Premade pouch rotary fill & seal machines can handle a wide range of pouch sizes, shapes, and materials, providing versatility in packaging options. They can accommodate various products such as powders, granules, liquids, and solids.

Product protection: These machines offer reliable sealing capabilities, ensuring the integrity and freshness of the packaged products. The tight seals protect against moisture, oxygen, and other environmental factors that could compromise the quality and shelf life of the contents.

4.Ease of operation: The machines are designed for user-friendly operation, with intuitive controls and easy changeover between different pouch sizes and products. Minimal operator training is required, reducing the chances of errors and improving overall productivity.

Customer site

Premade pouch rotary fill & seal packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

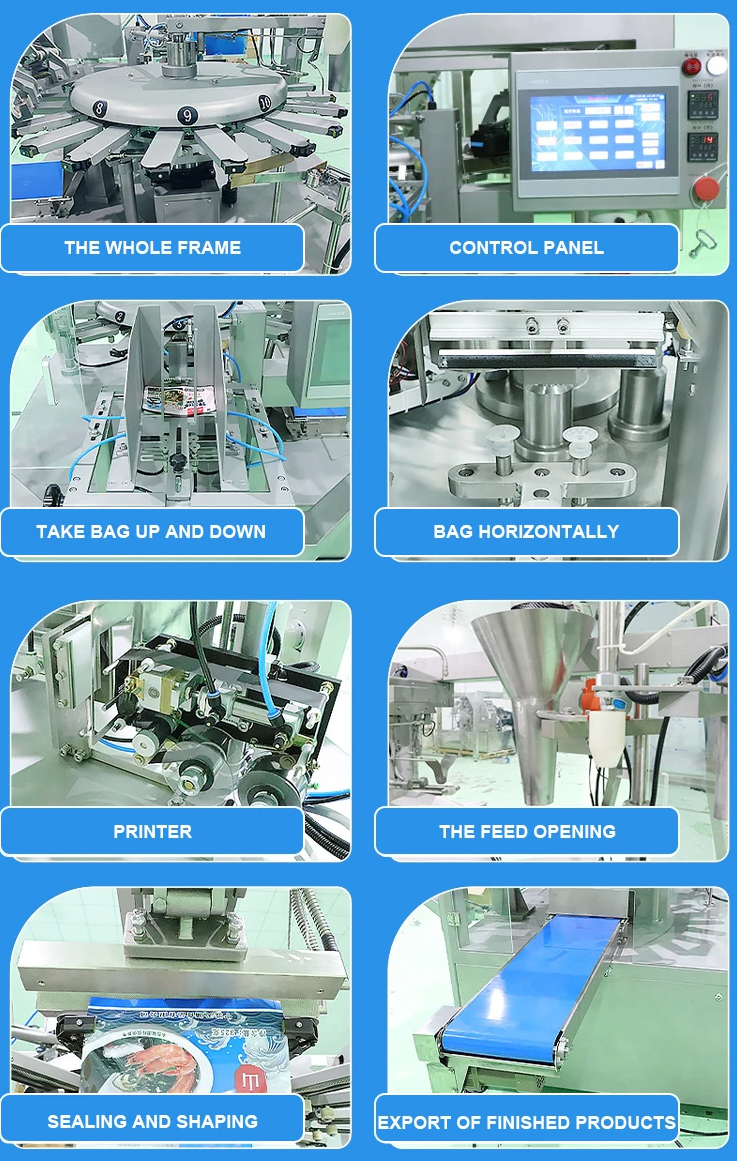

Structure of premade pouch rotary fill & seal packing machine

A premade pouch rotary fill & seal packing machine typically consists of a rotating carousel system that holds and transports the premade pouches through various stations. These stations include pouch opening, filling, sealing, and discharge. The machine is designed to automate the packaging process, ensuring efficient and accurate filling and sealing of the premade pouches.

Customer case

What about the premade pouch rotary fill & seal packing machine prcie?

The price of a premade pouch rotary fill and seal packing machine can vary depending on several factors, including the machine's brand, model, specifications, features, and the supplier or manufacturer you choose. Additionally, market conditions and any additional customization or optional accessories can also affect the price.

To get accurate pricing information for a premade pouch rotary fill and seal packing machine, I recommend contacting various suppliers or manufacturers directly. They will be able to provide you with specific pricing details based on your requirements and specifications. You can also consider requesting quotes or consulting with packaging machinery distributors or industry experts to get a better understanding of the price range for the machine you are interested in.

Why choose us as your premade pouch rotary fill & seal packing machine supplier?

Xinxiang Dahan is a professional manufacturer of premade pouch rotary fill & seal packing machine. We are customer-focused and committed to providing high quality, reliability and innovative packaging solutions. Their machines feature advanced technology and design, with efficient production capabilities and precise packaging performance. Through close cooperation with customers, Xinxiang Dahan understands their needs and provides customized solutions to help customers improve production efficiency, reduce costs, and achieve excellent packaging effects.