What is vertical form fill seal packing machines?

Vertical form fill seal packing machines (VFFS for short) is an automated packaging system that can automatically complete the entire process of film bag making, material metering and filling, sealing and cutting, and date printing, achieving efficient, hygienic, and precise automated packaging; it is widely used in food, medicine, chemicals, daily chemicals and other industries.

As a professional Vertical Form Fill Seal Packing Machines manufacturer, we provide a full range of solutions from single machines to full-line integration to meet the diverse packaging needs of customers in different industries. Our equipment adopts a modular design and can be flexibly adjusted according to the characteristics of customer products (such as granules, powders, and liquids) to ensure the best packaging effect.

What are the different types of vertical form fill seal packaging machines?

We at Vertical Form Fill Seal Packing Machines have vertical form fill seal packaging machines for powders, granules, liquids and pastes. Most of their parts are the same, only the feeding system is different. So if you want to buy a vertical packaging machine, we offer you various types of machines. But different packaging machines have different uses. Before buying vertical packaging equipment, you need to tell us the material you want to pack, the packaging speed, the budget, etc. So that we can recommend the most suitable machine according to your actual situation. We also support customized services.

Powder Vertical Form Fill Seal Packing Machines: These machines are designed to handle the packaging of powdered products such as spices, flour, milk powder, detergent, and other fine powders. They feature precise dosing systems, often auger fillers, to ensure accurate and consistent filling of the powder into the packaging bags.

Granule Vertical Form Fill Seal Packing Machines: Suitable for packaging granular products such as grains, nuts, snacks, coffee beans, pet food and other small solid items. They use volumetric fillers, weighing machines or combination scales to measure the granules and dispense them into packaging bags.

Liquid Vertical Form Fill Seal Packing Machines: Designed for liquid products, these machines package a wide range of liquids, including beverages, sauces, oils, dairy products, and personal care liquids. Liquid VFFS machines employ liquid pumps or piston fillers to ensure accurate filling and sealing of the liquid product in the bags, often incorporating special sealing techniques to prevent leakage.

Paste Vertical Form Fill Seal Packing Machines: It is a mechanical equipment used to pack paste or viscous materials. It can complete the operations of filling, sealing and sealing the materials. This machine is usually used in the food, cosmetics, medicine and other industries to pack sauces, pastes, jellies and other products.

How do vertical form fill seal packing machines work?

Vertical form fill seal packing machines work by using a continuous roll of packaging material to form a vertical tube, fill it with the product, seal it, and cut it into individual bags or pouches. The machine unwinds the packaging material, forms it into a tube, fills the product into the tube, seals it using heat or other methods, and then cuts and separates the sealed bags or pouches. These machines offer high-speed and efficient packaging, can handle various bag sizes and packaging materials, and are widely used in industries for automated packaging solutions.

Vertical Form Fill Seal Packing Machines with different motion modes

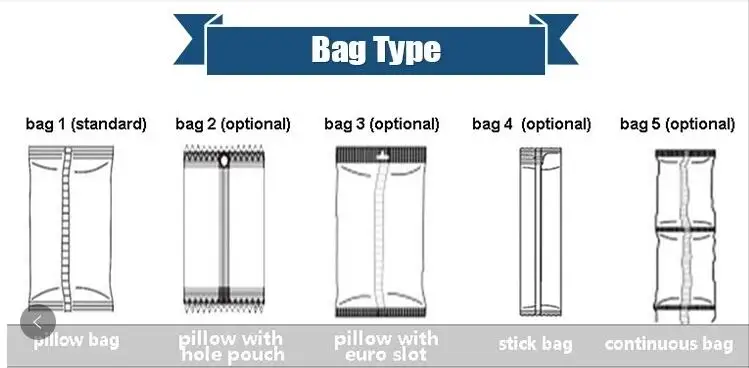

Intermittent motion Vertical Form Fill Seal Packing Machines are suitable for packaging one item or a group of items at a time, and are suitable for packaging tasks with small batches or low frequency of changes. It has reliable and consistent intermittent motion and can package pillow bags, 3 side seal bags, 4 side seal bags and stick bags.

Continuous motion Vertical Form Fill Seal Packing Machines are suitable for high-speed packaging lines and large-volume packaging tasks, and can achieve high efficiency, continuous production and automated operation. It has high-speed, reliable continuous motion. It can package pillow bags, side-supported pillow bags, 4-corner block bottom bags, block bottom bags, 4-corner seal bags, stick bags

What are the characteristics of vertical fill seal packaging machine?

Vertical Form Fill Seal Packing Machines adopts automatic operation, with high production efficiency and fast packaging speed. Here are some features of Vertical Form Fill Seal Packaging Machine:

Versatility: They can handle a wide range of products, from solids and liquids to powders and granules; they can also adapt to a variety of packaging materials, including plastic films, composite bags and specialty materials.

Flexibility: Flexibility in bag size, shape and design can be easily adjusted to suit different product sizes and packaging requirements.

Automation: Fully automated, it minimizes the need for human intervention, reduces labor costs, and improves production efficiency.

Hygiene: Hygienic and safe design: Food contact parts are made of 304 stainless steel, fully enclosed structure to prevent cross contamination, easy to disassemble and clean design, in line with food/pharmaceutical industry hygiene standards

Compact Design: The relatively compact structure makes it suitable for small and medium-sized production facilities, and its modular design also enables it to be easily integrated into existing production lines.

Vertical Form Fill Seal Packing Machines Video

Vertical form fill seal packing machines specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

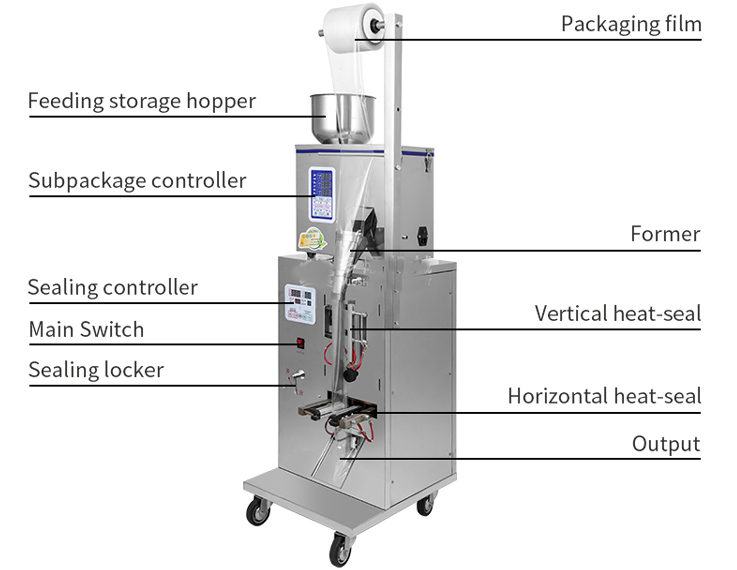

Structure of vertical form fill seal packing machines

Each component of the vertical form fill seal packaging machine plays a key role to achieve an efficient, accurate and reliable packaging process. Its structure mainly consists of the following parts:

Vertical form fill seal packing machines comprise a film unwinding system, a forming tube, filling and sealing systems, and a cutting unit. The film is unwound from a roll, formed into a vertical tube, filled with product, and sealed at the top and bottom. The filled package is then cut off from the tube and discharged from the machine.

What are the applications of vertical form fill seal packing machines?

Vertical form fill seal packing machines are versatile and can handle a variety of products, including solids, powders, granules, liquids, and even irregularly shaped items. Here are examples of some common product types that VFFS machines can package:

Packaging Materials

There are many kinds of packaging materials commonly used in Vertical Form Fill Seal Packing Machines, mainly plastic film, paper, composite materials, metal film, textile materials, etc. These materials can meet the packaging performance requirements of different products according to their materials, functions, and application fields.

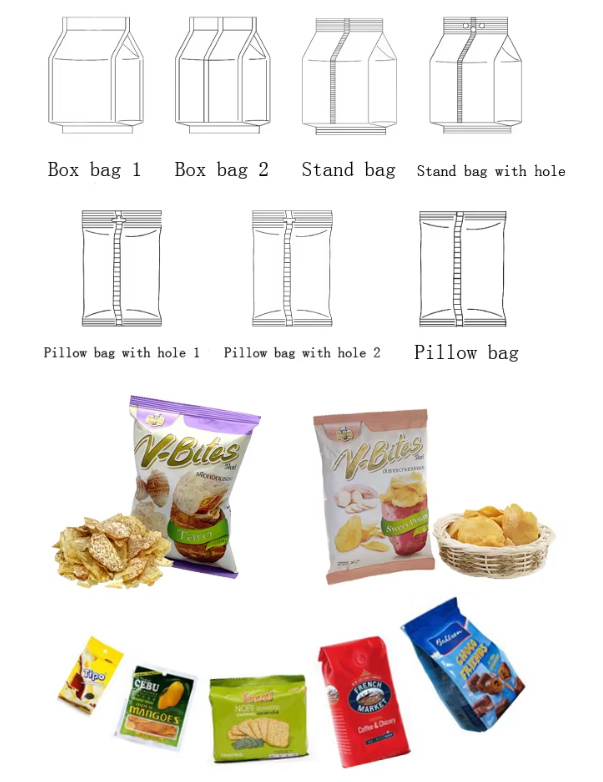

Packaging Style

Vertical Form Fill Seal Packing Machines can achieve a variety of packaging styles, the most common of which are back seal, three-side seal, center seal, four-side seal, pillow packaging, stand-up pouch packaging and Doypack packaging.

How to choose vertical form fill seal packing machines?

Product Characteristics: Consider the form (granules/powder/liquid), fluidity, corrosiveness and hygiene requirements of the product to be packaged.

Packaging Material: Select a machine compatible with the desired packaging material, such as plastic film, laminated pouches, or specialty materials.

Packaging Speed: Determine the desired production speed to meet your specific requirements.

Accuracy and Consistency: Ensure the VFFS machine can consistently produce pouches with accurate filling and sealing to maintain product quality and minimize waste.

Maintenance and Reliability: Consider the machine's ease of maintenance and reliability to minimize downtime and ensure continuous operation.

Integration and Compatibility: If the VFFS machine will be integrated into an existing production line, ensure compatibility with other equipment and seamless transfer of products.

What is the vertical form fill seal packing machines price?

The price of vertical form fill seal packing machines can vary significantly depending on various factors, including the machine's specifications, features, brand, and the supplier or manufacturer. Additionally, customization options, such as specific packaging requirements or additional features, can also affect the price.

As a result, it is challenging to provide an exact price range without specific details. However, VFFS packing machines typically range in price from a few thousand dollars for basic models to hundreds of thousands of dollars for high-speed, fully automated systems with advanced features.

How to choose a reliable vertical form fill seal packing machines manufacturer?

Choosing the right manufacturer for your vertical form fill seal packing machines is crucial to ensure you receive a reliable, high-quality machine that meets your specific requirements. Here are some factors to consider when selecting a VFFS packing machine manufacturer:

1. First of all, high-cost performance is the first principle. When choosing a packing machine manufacturer, we must pay attention to choosing a manufacturer with mature production technology and stable quality, so that the packaging can be faster and more stable, so as to achieve low energy consumption, low manual work, and low waste rate;

2. In terms of after-sales service, it is necessary to choose “in the circle” to have a good reputation. Timely after-sales service, available on call to ensure that the after-sales service is guaranteed;

3. The packaging machine trusted by the industry can be given priority, and it must be distinguished whether it is a manufacturer or a trading company;

4. Looking for professional custom design manufacturers. He can customize the design of the assembly line according to product characteristics, packaging film materials, and site conditions, and the production line is mature and complete.