What is vertical form fill seal packaging machines?

Vertical form fill seal packaging machines are commonly used in the packaging industry to automate the process of forming, filling, and sealing flexible pouches or bags. These machines are versatile and can handle a wide range of products, including solid, liquid, and powdered materials.

Vertical form fill seal packaging machines are versatile and efficient machines that can be used to package a wide variety of products. They are ideal for high-volume production runs and can be integrated with other packaging systems.

Types of vertical form fill seal packaging machines

Vertical filling and sealing packaging machine According to different production needs and scales, you can choose a suitable intermittent motion or continuous motion vertical filling and sealing packaging machine to meet the filling and sealing needs of the product.

Intermittent motion: This type of machine operates in an intermittent manner, that is, it only handles the filling and sealing of one bag at a time. This type of machine is suitable for smaller production batches, and the filling and sealing speed is relatively slow, but the operation is relatively simple.

Continuous motion: This type of machine operates in a continuous manner and can fill and seal multiple bags at the same time. The machine will not stop during operation, and continuously performs operations such as filling, sealing and sealing. It is suitable for mass production and can improve production efficiency, but it may be relatively complicated in operation and adjustment.

Live Video

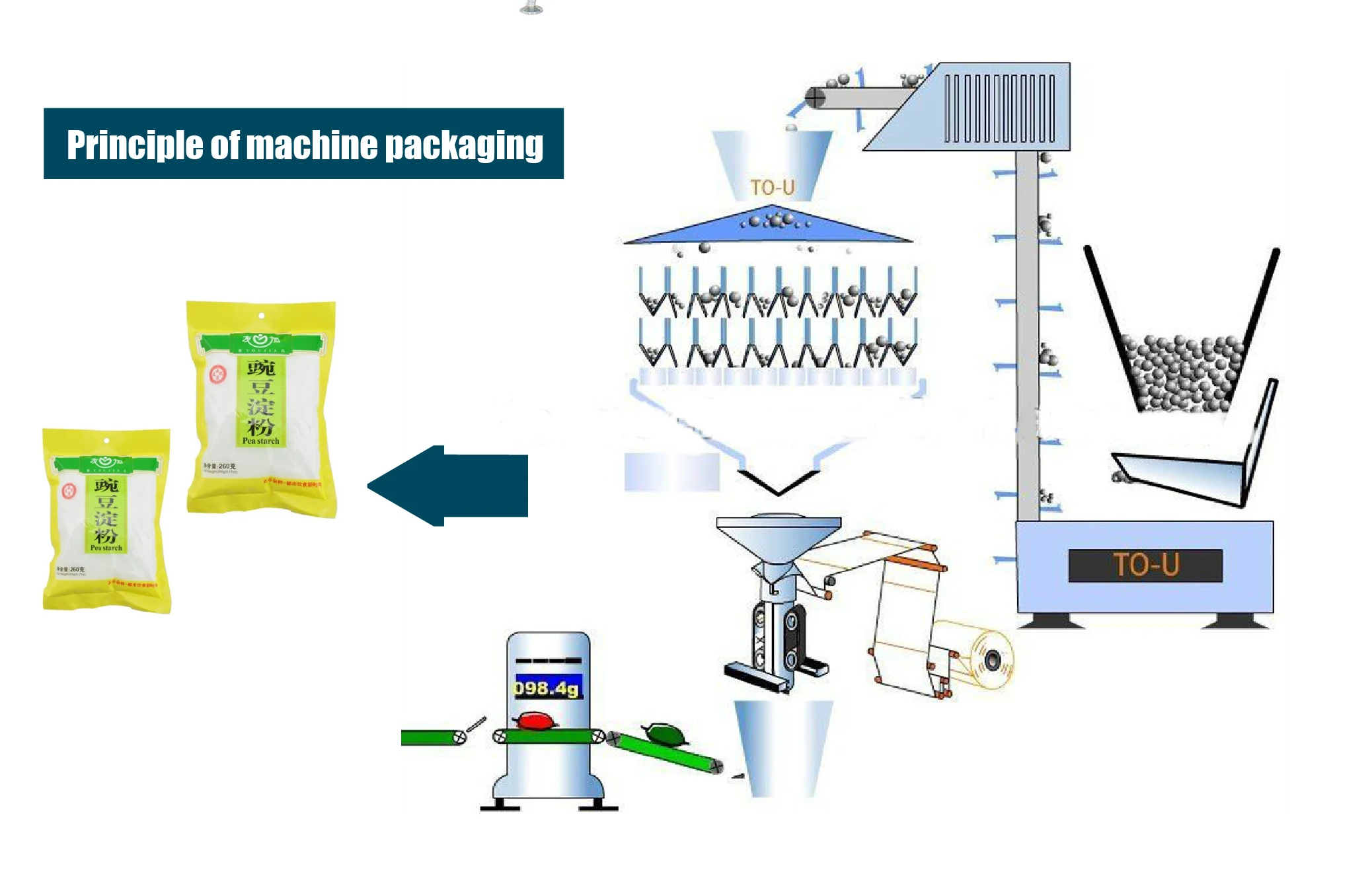

How do vertical form fill seal packaging machines work?

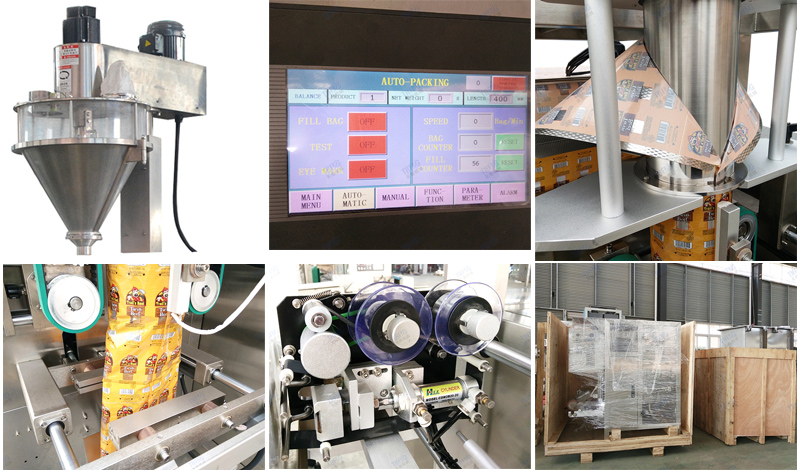

The vertical filling and sealing packaging machine has a workflow that includes preparation, filling, sealing and sealing, and product discharge. In the preparation stage, the packaging material is loaded into the feeding system and the machine parameters are set. Then, the product is transported to the filling part through the feeding system and filled according to the preset filling volume. After filling, select the appropriate method for sealing operation, and then, perform the sealing operation.

What are the applications of vertical form fill seal packaging machines?

Vertical form fill seal packaging machines are suitable for packaging various materials, such as popcorn, seeds, nuts, and other particles, or liquid and pastes such as water, beverages, chili oil, also can suit various powder packaging materials. It can satisfy the diverse needs of users and has a wide range of applications.

Food industry: biscuits, candies, potato chips, nuts, tea, coffee, quick-frozen dumplings, condiments, etc.

Beverage industry: such as juice, milk, tea, beer, carbonated drinks, sports drinks, energy drinks, plant drinks, etc.

Pharmaceutical industry: such as tablets, capsules, granules, powders, liquids, pastes, injections, infusions, medical devices, etc.

Chemical industry: such as fertilizers, pesticides, feed additives, pigments, dyes, paints, coatings, adhesives, detergents, etc.

Daily necessities industry: such as washing powder, laundry detergent, detergent, shower gel, shampoo, skin cream, toothpaste, soap, etc.

Features of vertical form fill seal packaging machines

Packaging flexibility: VFFS machines can accommodate different bag sizes and styles, allowing for flexibility in packaging options. They can produce various bag types, such as pillow bags, gusseted bags, quad seal bags, or stand-up pouches, to meet specific product and branding needs.

Efficiency and speed: VFFS machines offer high-speed packaging capabilities, enabling efficient production rates and increased productivity. They can handle a large volume of products in a relatively short time, reducing labor costs and improving overall operational efficiency.

Product protection: VFFS machines provide excellent product protection by creating a sealed and airtight package. This helps preserve product freshness, extend shelf life, and prevent contamination or spoilage.

Integration and automation: VFFS machines can be integrated into production lines and connected to other equipment, such as product feeders, conveyors, or labeling machines, for seamless automation and improved production flow.

Versatility: VFFS machines can package a wide range of products, including food items (snacks, grains, coffee, etc.), pet food, pharmaceuticals, cosmetics, and more. They can handle different product consistencies, from powders and granules to liquids and viscous substances.

Vertical form fill seal packaging machines specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

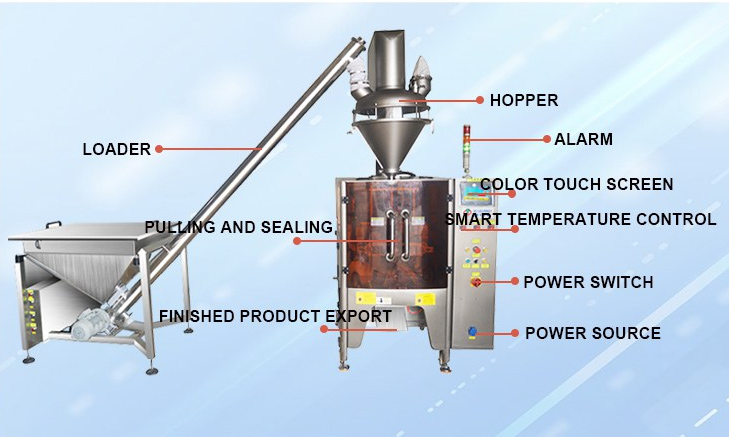

Structure of vertical form fill seal packaging machines

Vertical form fill seal (VFFS) packaging machines are automated machines used in industries like food, pharmaceuticals, and consumer goods. They form, fill, and seal flexible bags or pouches in a vertical orientation. The process involves unwinding packaging film, forming a tube, filling the product, sealing the pouches, and cutting them off. VFFS machines offer versatility, efficiency, flexibility, product protection, and cost-effectiveness in packaging operations.

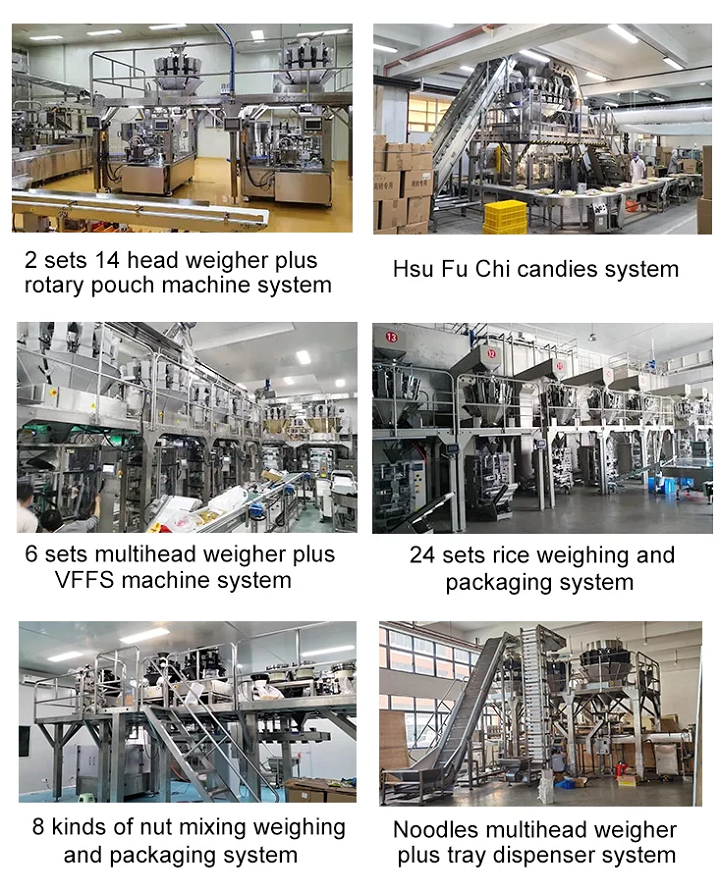

Customer case

| Application scenario | Packaging material | Packaging quantity | Packaging size |

| A food processing plant in Australia uses Vertical Form Fill Seal Packing Machines to automatically package wet noodles to improve production efficiency and hygiene standards. | Wet noodles | 20-100 bags can be packed per minute | Bag width up to 300mm, bag length range is 100-300mm, suitable for wet noodles of various specifications |

| A salt company in Pakistan uses VFFS packaging machine to pack salt at high speed to meet large-scale production needs. | Salt | The equipment is designed to run continuously and efficiently, and can pack thousands of bags per hour | Supports a variety of bag types, including pillow bags and self-supporting bags, and bag length and width can be customized according to customer needs |

| A snack manufacturer in the United States uses VFFS packaging machine to automatically pack puffed foods to ensure product sealing and freshness. | Puffed food (such as potato chips, corn chips) | 30-50 bags can be packed per minute | The maximum bag width is 330mm, and the bag length range is 150-240mm, which is suitable for packaging puffed food of various specifications. |

What’s the vertical form fill seal packaging machines price?

The price of vertical form fill seal (VFFS) packaging machines can vary widely based on several factors, including the machine's specifications, features, brand, and the region where it is purchased.

To get accurate pricing information, it is recommended to reach out to multiple suppliers or manufacturers of VFFS machines, provide them with your specific requirements, and request detailed quotations. This will help you obtain precise pricing tailored to your needs and allow you to compare options before making a decision.

How to choose vertical form fill seal packaging machines?

Choosing the right vertical form fill seal (VFFS) packaging machine is crucial to ensure efficient and effective packaging operations. Here are some key factors to consider when selecting a VFFS machine:

1.Packaging Requirements:

Determine the desired packaging format, such as pouches, bags, or sachets, and consider the required bag dimensions, sealing methods (e.g., heat sealing, ultrasonic sealing), and additional features like tear notches or zippers. Ensure that the VFFS machine can accommodate your desired packaging specifications.

2.Production Capacity:

Evaluate your production requirements, including the desired output or packaging speed. Choose a VFFS machine that matches or exceeds your production needs to maintain efficiency and meet demand.

3.Machine Flexibility and Adjustability:

Assess the reliability and durability of the VFFS machine. Look for machines from reputable manufacturers known for producing high-quality equipment. Read customer reviews, seek recommendations, and consider the machine's warranty and after-sales support.

Vertical Form Fill Seal machine manufacturers

Xinxiang Dahan is a manufacturer specializing in the production of vertical form fill seal packaging machines. They offer various types and specifications of VFFS packaging machines suitable for the product packaging needs of different industries. Xinxiang Dahan is known for its high-quality machines, reliable performance and excellent after-sales service. They are committed to providing customers with customized solutions that meet their specific needs and ensure an efficient, precise and reliable packaging process.