Protein Powder for Vertical Automatic Packaging Machine

Protein Powder for Vertical Automatic Packaging Machine refers to specialized pre-made pouches, roll films, and filling systems designed to automate the packaging of protein supplements (like whey, plant-based, or collagen powders) in high-speed production lines. These dust-proof, anti-static materials ensure precise, hygienic, and efficient filling (up to 80 bags/min) while preventing clumping or spillage. Compatible with vertical form-fill-seal (VFFS) machines, they support custom sizes (20g-1kg), FDA-approved barrier films, and branded printing—perfect for sports nutrition brands, supplement manufacturers, and food processors seeking tamper-evident, airtight, and retail-ready packaging.

Live video

What is the application scope of protein powder vertical automatic packaging machine?

Protein powder vertical automatic packaging machines are widely used in the food industry and health care products industry. The following are some application scenarios of protein powder vertical automatic packaging machines:

Protein powder packaging: mainly used for the packaging of protein products such as protein powder, protein supplements, protein drinks, etc., to ensure the accurate weight of the product and neat packaging.

Health care product packaging: suitable for the packaging of health care products such as health care powder, dietary supplements, vitamin powder, etc., to ensure the hygiene and safety of the product and stable quality.

Milkshake powder packaging: used for the automatic packaging of milkshake powder, instant milkshake, milkshake drink powder and other products to improve production efficiency and packaging quality.

Protein drink packaging: suitable for the automatic packaging of protein drink powder, protein drink mixed powder and other products to ensure the packaging standards and hygiene requirements of the products.

Other powdered product packaging: In addition to protein powder products, it can also be used for the packaging of other powdered products, such as coffee powder, flour, seasonings, etc.

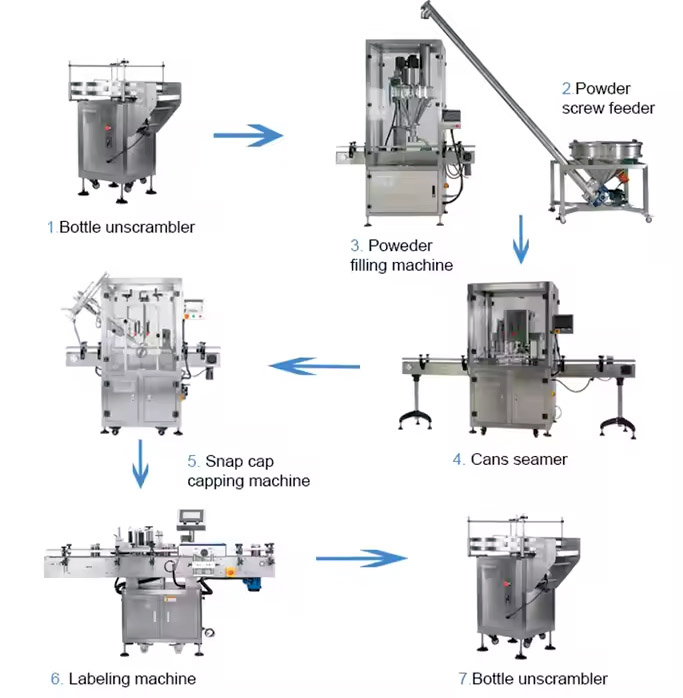

How does the protein powder vertical automatic packaging machine work?

The working principle of the protein powder vertical automatic packaging machine generally includes the following steps:

Feeding stage: The protein powder to be packaged is transported to the working position of the packaging machine through the feeding system.

Weighing stage: The protein powder contacts the weighing system, and the system weighs it according to the preset parameters. The high-precision weighing system ensures that the weight of each bag of product is accurate.

Filling: The weighed protein powder is filled into the pre-prepared packaging bag.

Sealing: After the packaging bag is filled, the bag mouth is sealed by the sealing device to ensure the sealing and freshness of the product.

Output stage: The packaged protein powder bag is output from the machine and can be further packaged, stored or transported.

What are the advantages of protein powder vertical automatic packaging machine?

Blazing Speed – Pack 40-100 bags per minute (vs. manual packing at 10-15 bags), ideal for high-volume production.

Pinpoint Accuracy – Advanced auger fillers & load cells ensure ±1% weight tolerance, eliminating costly overfills or underfills.

Zero Contamination – Stainless steel contact parts & dust-proof sealing meet FDA & GMP standards, keeping protein powder pure.

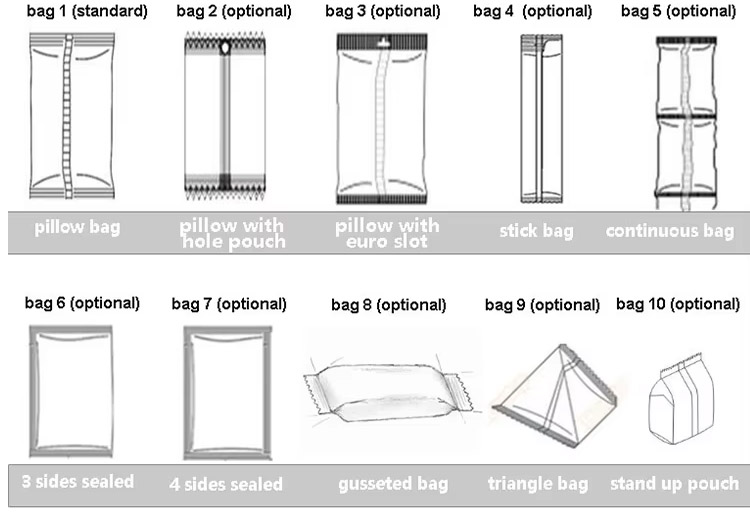

Custom Packaging – Handles stick packs (30-50g), stand-up pouches (1-5kg), and bulk bags (10-25kg) with quick mold changes.

Smart Automation – Self-adjusting sensors detect film misalignment, auto-reject defects, and print batch codes/expiry dates911.

Cost Savings – Slashes labor by 70%+ and reduces material waste with anti-static, nitrogen-flushed bags for longer shelf life.

What is the best packaging for protein powder?

The best packaging for protein powder combines durability, freshness protection, and consumer convenience—typically using multi-layered stand-up pouches with resealable zippers (for easy scooping), UV-blocking materials to prevent nutrient degradation, and FDA-approved barrier films to block moisture and oxygen. For premium brands, opaque, BPA-free plastic tubs with airtight seals are ideal, while eco-conscious lines opt for compostable pouches or recyclable metalized bags. Key features include anti-static liners to prevent clumping, branded tamper-evident labels, and scoop compartments for mess-free use.

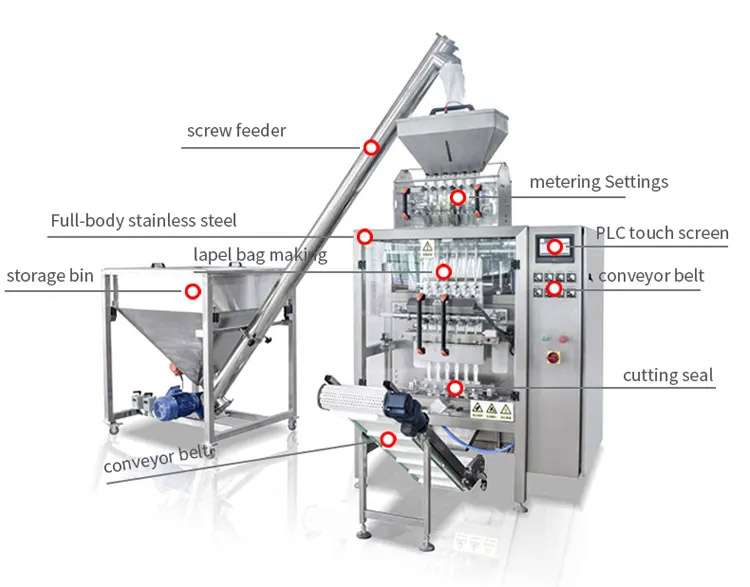

What are the structures of protein powder vertical automatic packaging machine?

Protein powder vertical automatic packaging machine usually includes the following main structural components:

Feeding system: used to transport the protein powder or other products to be packaged to the working position of the packaging machine.

Weighing system: This system is used to accurately weigh the weight of the protein powder in each packaging bag.

Packing mechanism: This part is responsible for filling the weighed protein powder into the packaging bag.

Control system: The automatic packaging machine is equipped with a control system to monitor and control the entire packaging process to ensure the accuracy and stability of the operation.

Human-machine interface: Includes an operation panel or screen for operators to interact with the automatic packaging machine, set parameters, monitor the production process, etc.

Safety devices: The equipment is usually equipped with various safety devices, such as protective covers, emergency stop switches, etc., to ensure the safety of operators and equipment.

Protein Powder for Vertical Automatic Packaging Machine Customer Case

| Customer Cases | Application Scenarios | Packing Volume | Packing Speed | Packing Size | Solution Highlights |

| American Sports Nutrition Brand (Whey Protein) | High-end Whey Protein Powder Retail Packaging (Gym/E-commerce Channel) | 1kg / 2.2lb | 40-50 bags/min | 180mm × 300mm stand-up bag | Nitrogen filling for freshness preservation, laser anti-counterfeiting label, automatic weight check and rejection |

| European plant protein manufacturer (Pea Protein) | Organic pea protein powder wholesale packaging (supermarket supply chain) | 5kg / 11lb | 25-30 bags/min | 250mm × 400mm four-side sealed bag | Anti-static inner film, UV blocking layer, automatic pallet stacking |

| Asian meal replacement powder OEM factory (Meal Replacement) | Small-sized portable packaging for meal replacement powder (subscription delivery) | 50g / 1.76oz | 60-70 stick packs/min | 30mm × 150mm stick pack | Thermal transfer QR code<, easy-tear design, multi-flavor mixed packing mode |

Protein powder vertical automatic packaging machine manufacturer

Dahan protein powder vertical automatic packaging machine is a manufacturer specializing in the research and development, production and sales of automatic packaging machinery. Our protein powder vertical automatic packaging machine adopts the most advanced technology and materials, with a high-precision weighing system, a stable and reliable packaging mechanism and an intelligent control system. Our products are reliable in quality and superior in performance, and are widely used in food, health care products and other industries. We adhere to the business philosophy of "quality first, customer first" and are always committed to providing customers with high-quality products and professional after-sales service. We have an experienced and skilled R&D team and after-sales service team to provide customers with a full range of technical support and solutions. If you have packaging needs, please feel free to contact us!

Thursday September-04 2025 16:38:21