Small Bag Snack for Vertical Weighing Automatic Packaging Machine

Small Bag Snack for Vertical Weighing Automatic Packaging Machine is a device specially used for weighing and packaging small bag snack products. It combines weighing and packaging functions and can efficiently and accurately complete the packaging process of snack products. It is usually used for weighing, measuring and packaging small bag snacks, such as potato chips, melon seeds, nuts, candies, etc.

Live video

What are the applications of Small Bag Snack for Vertical Weighing Automatic Packaging Machine?

Small Bag Snack for Vertical Weighing Automatic Packaging Machine is widely used in the food industry, especially for enterprises that produce and pack small bag snacks, this equipment is very important. The following are some of the main application areas of Small Bag Snack for Vertical Weighing Automatic Packaging Machine:

Puffed Snacks – Perfect for chips, popcorn, and corn flakes with exact weight control.

Nuts & Seeds – Handles peanuts, almonds, and walnuts for high-speed, consistent packaging.

Candy & Chocolate – Ensures neat, accurately weighed small-bag portions.

Dried Fruits – Ideal for raisins, cranberries, and apricots, boosting productivity.

Mix-and-Match Snacks – Weighs and packs multi-product combos seamlessly.

Sealed Freshness – Keeps瓜子 (melon seeds), preserved fruits, and more fresh & hygienic.

Single-Serve Packs – Optimizes chewing gum, mini cookies, and other on-the-go snacks.

Custom Packaging – Tailors bag sizes, shapes & materials to brand needs.

How does the Small Bag Snack for Vertical Weighing Automatic Packaging Machine work?

The Small Bag Snack for Vertical Weighing Automatic Packaging Machine consists of several integrated systems to ensure efficient and accurate snack packaging. The feeding system transports small bag snacks to the packaging machine's working area, while the weighing system—comprising a load sensor, controller, and weighing platform—precisely measures each snack's weight to meet preset requirements. The packing system then fills and seals the weighed snacks into small bags. Overseeing the entire process, the PLC control system monitors and adjusts each component's operation for smooth workflow. Finally, the discharge system removes the packaged snacks from the machine, typically via a conveyor belt or similar device, facilitating subsequent packaging, storage, or transportation.

Snacks enter via conveyor → High-precision sensors weigh (±0.1g) → Pre-made bags auto-fill → Heat-sealed for freshness → Finished packs exit at 30-60 bags/min. Fully automated, zero waste!

What are the advantages of Small Bag Snack for Vertical Weighing Automatic Packaging Machine?

Precision Weighing – High-accuracy sensors ensure ±0.1g consistency for snacks, nuts & candies.

High-Speed Automation – Pack 30-60 bags/min, slashing labor costs by 50%.

Multi-Format Flexibility – Handles pillow packs, stand-up pouches & more (5g-500g).

Smart Integration – PLC touchscreen control, QR coding & FDA/CE compliance.

Durable & Hygienic – Food-grade stainless steel, easy-clean design.

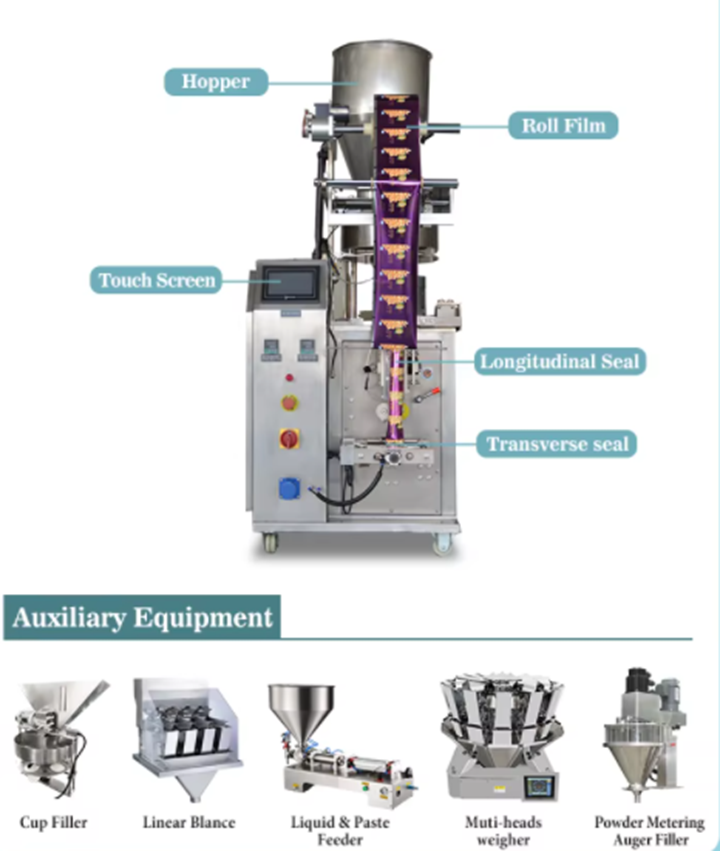

Small Bag Snack for Vertical Weighing Automatic Packaging Machine Composition Structure

Small Bag Snack Vertical Weighing Automatic Packaging Machine usually consists of the following main parts, each of which has a specific function and works together to complete the automatic packaging work:

Feeding system: The feeding system is used to transport the small bag snacks to be packaged to the working area of the packaging machine.

Weighing system: The weighing system usually includes a load sensor, a controller and a weighing platform to accurately measure the weight of each small bag snack and ensure that it meets the preset weight requirements.

Packing system: The packaging system is responsible for filling the weighed snacks into the small bag and sealing it.

PLC control system: The control system is the brain of the entire packaging machine, responsible for monitoring and adjusting the operation of each component to ensure the smooth progress of the entire packaging process.

Discharge system: The discharge system discharges the packaged small bag snacks from the packaging machine, usually through a conveyor belt or other discharge device, which is convenient for subsequent packaging, storage or transportation.

Small Bag Snack for Vertical Weighing Automatic Packaging Machine Customer Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A well-known potato chip brand needs to pack bulk potato chips into 25g small bags, requiring high-precision weighing and anti-shatter packaging. | 25g/bag (±0.2g error) | 50 bags/minute (dual-channel weighing system) | 90mm(W) × 120mm(H) (pillow bag) | PET/AL/PE composite film (moisture-proof + light-proof) |

| Export-grade mixed nuts (almonds/cashews/walnuts) need to be packaged in 50g portable self-supporting bags. | 50g/bag (±0.3g error) | 40 bags/minute (with multi-head combination weigher) | 100mm(W) × 150mm(H) (self-supporting zipper bag) | KNY/PE (high barrier and anti-oxidation) |

| Freeze-dried chicken cubes are packaged in 10g small bags and must meet FDA food grade standards. | 10g/bag (±0.1g error) | 60 bags/minute (high-speed servo drive) | 70mm(W) × 100mm(H) (back seal bag) | Pure aluminum foil (anti-mold + fresh-keeping) |

What is the price of Small bag snack vertical weighing automatic packaging machine?

Dahan Small Bag Snack Vertical Weighing Automatic Packaging Machine Manufacturer is committed to providing efficient and accurate packaging solutions for the food industry. We have many years of experience and a professional team, and can customize various types of packaging machines according to customer needs. The price generally ranges from thousands to tens of thousands of dollars. The specific price depends on the specifications of the equipment, such as weighing range, packaging speed, degree of automation, etc. At the same time, additional configurations such as printing function, multi-head weighing system, pneumatic sealing and other functions will also affect the price. If you have any needs, please feel free to contact us!

1. Model & Price Range

HDL-F60C Powder Packaging Machine Price: $3,100–$32,000,Auger screw filling, 3 or 4-side sealing, 40–60 bags/min speed.

Speedpack Hybrid 400 (Audion Packaging Machines) Price: $7,000–$15,000, Handles small bags (5×8 cm to 40×80 cm), 20–60 bags/min, flexible film/pre-opened bag options.

ZONPACK ZH-V320 Vertical Packing Machine Price: $9,000–$15,000. Multihead weigher integration, 4-side sealing, suitable for snacks, nuts, and coffee beans.

2. Material

Most machines use stainless steel contact parts (for food safety) with Q235 carbon steel or aluminum alloy frames.

Some models offer GMP-standard construction for hygiene-sensitive industries like food and pharmaceuticals.

3. Packaging Capacity

Small snack bags typically range from 1–100 ml (for powders like spices) up to 25–100 g (for nuts, chips).

Bag dimensions vary: HDL-F60C: 30–50mm (L) × 25–100mm (W); Speedpack Hybrid 400: 5×8 cm to 40×80 cm.

4. Packaging Speed

Entry-level machines: ~20–40 bags/min (semi-automatic models).

High-speed models: 40–60 bags/min (e.g., HDL-F60C, ZH-V320)

Thursday September-04 2025 16:37:35